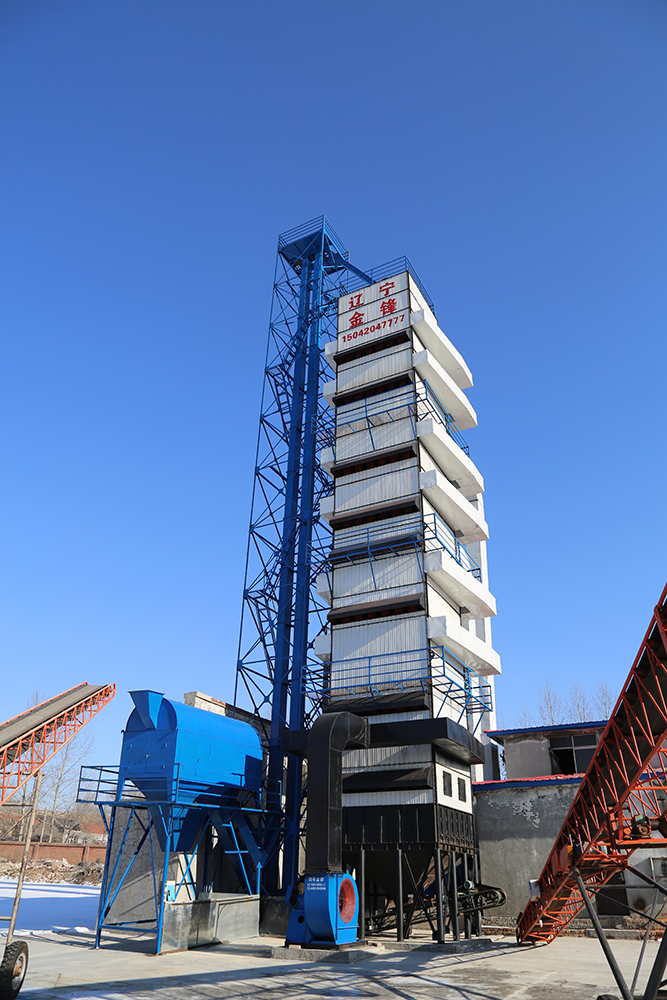

High Capacity Wheat Rice Corn Grain Dryer

Basic Info

Model No.: 5HSNM-200

Product Description

High Capacity Wheat Rice Corn Grain Dryer

The Corn Dryer is a drying machine that can dry a variety of materials and has a simple and reliable operation. Due to the reliable operation of the dryer, strong adaptability and large processing capacity, the dryer is widely used in metallurgy, building materials, food, light industry, chemical industry, In the coal, pharmaceutical and mining industries. It is widely used. Loved by users. In order for the dryer to be used, the following conditions must be done:

1. Check all moving parts, bearings, conveyor belts, and V-belts for damage before operation. Repair or replace improper parts in time.

2. Lubrication and maintenance, every 100 hours of operation of the hot air fan, and supplement of lubricating oil every 400 hours of operation of the cold air fan. Every 1000 hours of motor operation, maintenance and replacement of butter. Lifting and conveyor bearings are filled with lubricant for every maintenance.

3. Repairing vulnerable parts: bearings, bearing seats, lifting buckets, lifting bucket screws are easy to loosen, and must be repaired and protected frequently. Conveyor bearings and adhesive tape buckles should be checked and replaced frequently. Electrical appliances and moving parts should be overhauled frequently. Attention to maintenance

4. Seasonal replacement protection, the dryer should be protected every season of the operation, the dryer should sort out the debris in the inner air duct, the elevator should loosen the tension wire, the fan should sort out the adhesion of the fan blade, and the hot air furnace exchanger should Clean up the ash deposits in the sedimentation tank, and arrange the pipelines one by one. The speed regulating motor speed meter returns to zero standby.

5. If the dryer is operated outdoors, it is necessary to take corresponding rain and snow protection measures. The whole machine needs to be protected and repaired on a large scale every year, and paint spray protection is required every two years.

Grain Dryer Technical Parameter Table

| project

model | corn |

Rice

| Installed capacity(KW) | Hot stove ( 10'kcalh) | ||||

| Daily processing capacity T/D | Tax reduction% | Hot air temperature ℃ | Daily processing capacity T/D | Tax reduction% | Hot air temperature ℃ | |||

| SNH-5 | 100 | 10-15 | 120-150 | 200 | 2-3 | ≤50 | 41.35-63.25 | 120 |

| SNH-7.5 | 150 | 10-15 | 120-150 | 300 | 2-3 | ≤50 | 62.55-82.75 | 180 |

| SNH-10 | 200 | 10-15 | 120-150 | 350 | 2-3 | ≤50 | 81.95-106.25 | 240 |

| SNH-15 | 300 | 10-15 | 120-150 | 550 | 2-3 | ≤50 | 106.25-143.45 | 360 |

| SNH-20 | 400 | 10-15 | 120-150 | 700 | 2-3 | ≤50 | 193.4-203.4 | 480 |

| SNH-25 | 500 | 10-15 | 120-150 | 800 | 2-3 | ≤50 | 240.9-251.9 | 600 |

| SNH-30 | 600 | 10-15 | 120-150 | 1000 | 2-3 | ≤50 | 272.8 | 720 |

| SNH-40 | 800 | 10-15 | 120-150 | 1300 | 2-3 | ≤50 | 406.8 | 960 |

| SNH-50 | 1000 | 10-15 | 120-150 | 1800 | 2-3 | ≤50 | 508.4 | 1200 |

After-sales Commitment

★ We have complete customer files for our products, and provide technical guidance and accessories supply for life.

★ Dryer complete sets of equipment, within a drying period, such as the manufacturer's quality reasons to provide "three guarantees" service.

★ Respond to customer's use failure within 4 hours and provide initial solution.

★ After-sales service phone is turned on 24 hours a day to provide you with feedback on technical quality and problem reasons.

★ Respond within 48 hours to provide door-to-door service upon request of the user (the time will increase or decrease due to the distance of the area)

Jinfeng Drying Equipment Co., Ltd. of Qinghe District, Tieling City, Liaoning Province, is a professional manufacturer mainly manufacturing grain drying equipment and electronic truck scales. The company has more than 180 employees, including 76 engineering and technical personnel. The company has a high-quality production and manufacturing team, product research and development team, marketing and sales team, and enterprise management team. It has advanced production lines and testing methods to provide new products for the majority of users. High-quality services such as development and design, equipment manufacturing, installation, debugging and maintenance.

For many years, our company has insisted on "survive by quality, promote development by credibility", adopts the advanced technology of "low temperature drying", has developed three series of cross flow, forward and backward flow and mixed flow, and more than ten varieties of grain Dryer, RFL series coal-fired hot blast stove, DTJ series low crushing bucket elevator, drum-type primary cleaning screen, grain conveyor series products and power distribution system, the complete set of equipment are independently developed, designed and manufactured by our company. According to customer needs, automatic temperature control, automatic control of material level and fault safety protection devices can also be added. The product is suitable for drying grains such as corn, rice, wheat and soybeans and drying other granular materials such as cotton.

The SCS-10-150 series truck scales and quantitative packing scales produced by our company have superior performance, high precision and good stability.

Our company adheres to the business philosophy of "quality assurance, customer first", with high-quality products, reasonable prices and perfect after-sales service, we sincerely welcome the presence of our friends!

Product Categories : Grain Dryer > Corn Dryer